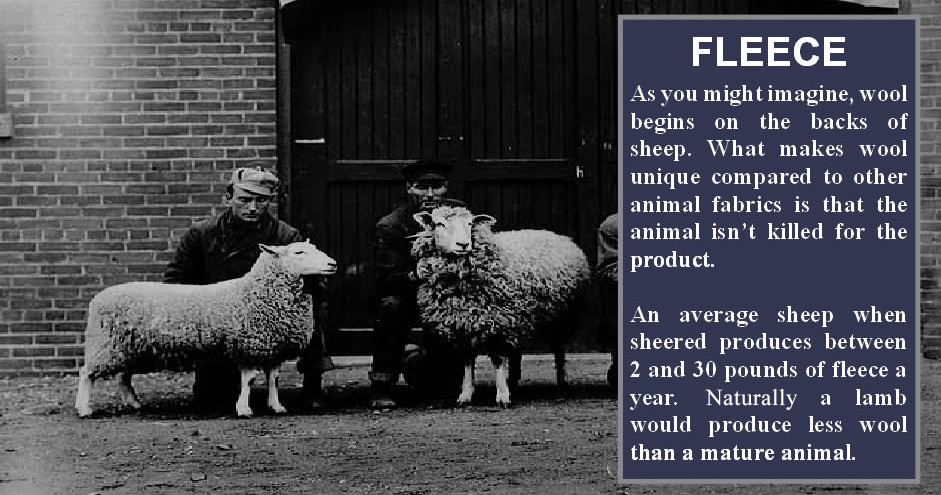

As you might imagine, wool begins on the backs of sheep. What makes wool unique compared to other animal fabrics is that the animal isn’t killed for the product. An average sheep when sheered produces between 2 and 30 pounds of fleece a year. aturally a lamb would produce less wool than a mature animal.

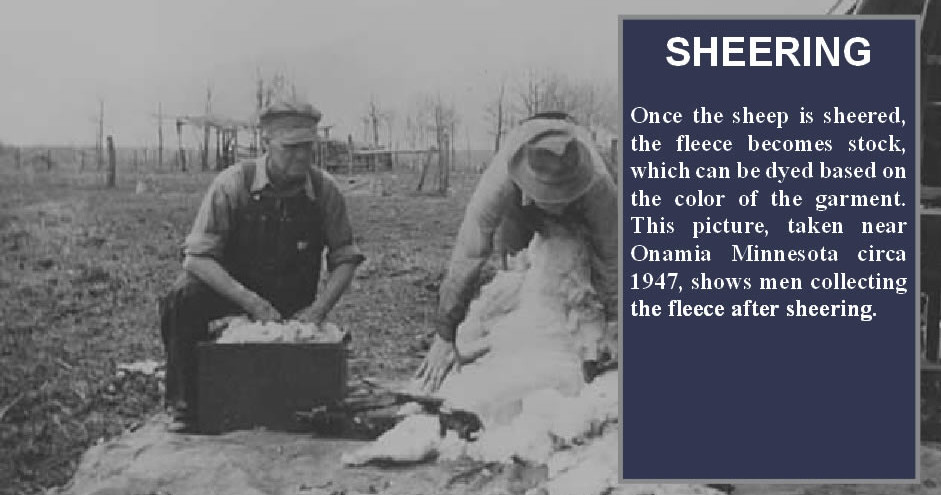

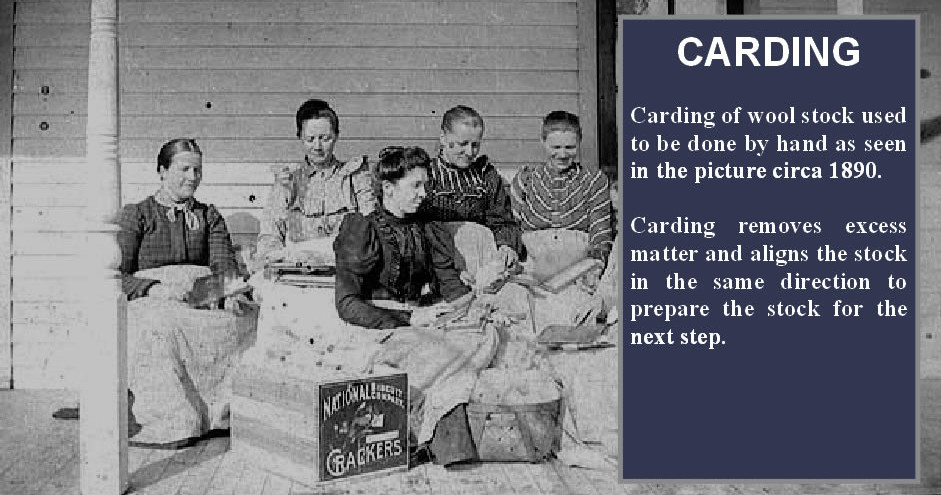

Once the sheep is sheered, the fleece becomes stock, which can be dyed based on the color of the garment. The stock is than washed and goes through a carding machine. Carding of wool stock used to be done by hand as seen in the picture circa 1890 and compliments of the Minnesota historical society. Carding removes excess matter and aligns the stock in the same direction to prepare the stock for the next step.

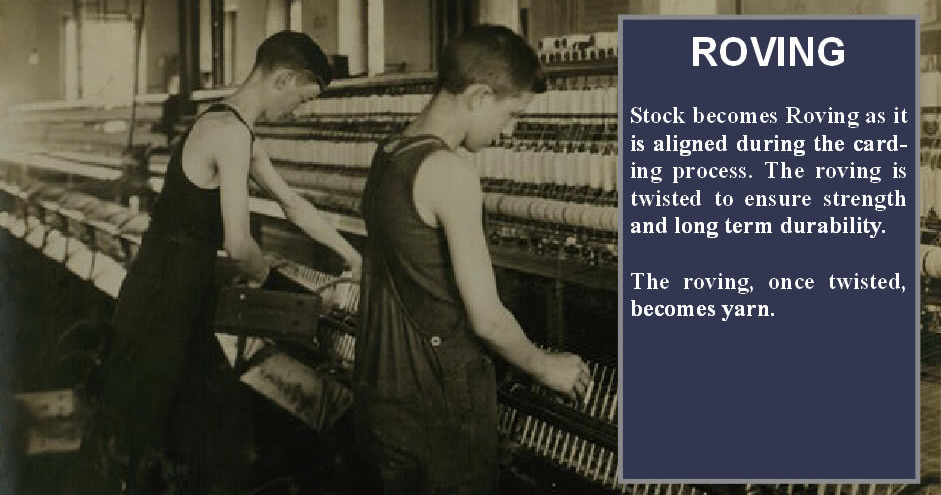

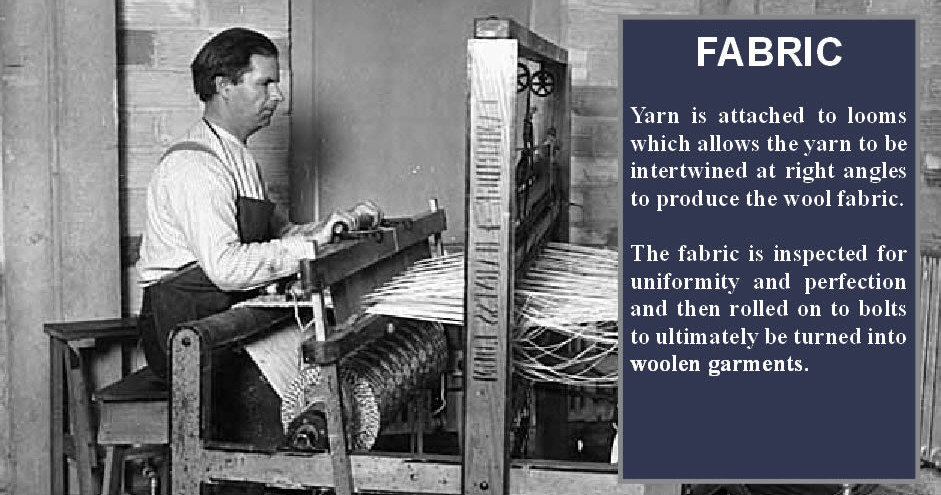

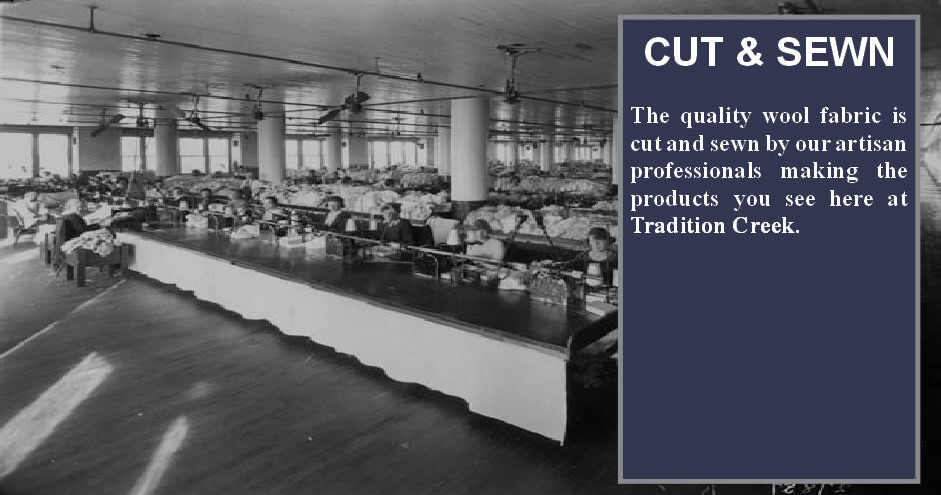

Stock becomes Roving as it is aligned during the carding process. The roving is twisted to ensure strength and long term durability. The roving, once twisted, becomes yarn. The yarn is attached to looms which allows the yarn to be intertwined at right angles to produce the wool fabric. The fabric is inspected for uniformity and perfection and then rolled on to bolts. The quality wool fabric is cut and sewn by our artisan professionals making the products you see here at Tradition Creek.